AIR BRAKE Interactive General Driver Education Edition (ABI-GDE)

Why Air Brake Training for Drivers?

A heavy vehicle’s air brakes are its single most important safety system. Although drivers in most jurisdictions are required to know something about the air brake systems employed on their vehicles, in many cases the required curriculum is woefully inadequate. As a result many commercial vehicle drivers simply do not know enough about their vehicle’s air brakes to recognize when they are functioning properly and when they are not.

The following supports this position:

December 2008 – The American Association of Motor Vehicle Administrators

Because no driver training standards exist, many drivers are trained primarily to pass the State knowledge and skills tests. The Task Force believes a gap exists between the testing required by the CDL program and the knowledge and skills needed to safely operate a CMV.

February 2006 – NTSB Acting Chairman Mark V. Rosenker said, “We believe that more than 500,000 vehicles equipped with air brakes may be operated by drivers who have no air brake training and therefore may not be able to operate their vehicles safely. This situation needs to change – and change quickly.”

The Solution

The solution to inadequate driver knowledge regarding air brake systems is obviously education – thorough education as opposed to just enough knowledge to acquire a CDL. Understanding air brake systems is not difficult, provided that instructors themselves have the knowledge required to properly teach the subject and are equipped with comprehensive and effective teaching resources. Our AIR BRAKE Interactive General Driver Edition teaching resource fits and fills that requirement like no other program available.

What is AIR BRAKE Interactive GDE?

AIR BRAKE Interactive General Driver Education Edition (ABI-GDE) is a comprehensive, ready-to-present, air brake teaching resource for professional driver trainers. It is designed to provide driver trainers with the information and visual teaching resources they need to ensure that their students fully understand the design, operation and routine inspection and maintenance requirements of modern heavy vehicle air brake systems.

With ABI-GDE you will deliver a comprehensive and consistent training message, every time! Your students will learn faster and comprehend and retain more information than has ever before been possible! The result is better informed drivers who fully understand the issues associated with air brake system operation, inspection, adjustment and routine maintenance.

GDE Instructor’s Reference and Presentation Guide

The GDE Instructor’s Reference and Presentation Guide is a full color, 12-module, 260-page publication designed to guide the instructor through his or her GDE presentation from beginning to end. It is also a comprehensive technical reference for instructors, providing presentation tips, suggestions for student exercises and notes regarding specific components and related issues.

The Multimedia Presentation

The GDE multimedia presentation includes 44 voice-narrated air brake component and system animations and 80 additional high quality support visuals. Ultimately, you students will see, hear and remember how an entire modern air brake functions. It’s Visual Learning at it best!

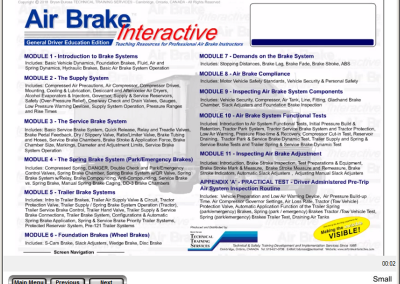

ABI-GDE Content

MODULE 1 – Introduction to Brake Systems

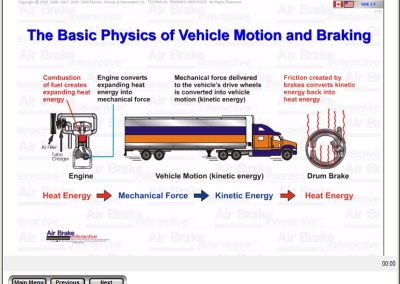

• Basic Physics of Vehicle Motion and Braking (How Brakes Slow and Stop a Vehicle)

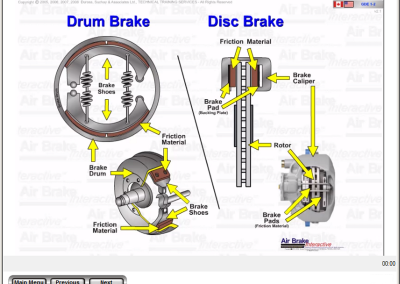

• Brake Basics – Foundation Brake Types

• Drum Brakes – Principal Components and Basic Operation

• Disc Brakes – Principal Components and Basic Operation

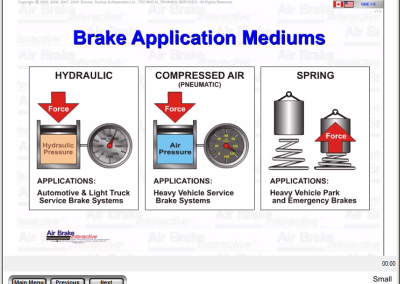

• How Brakes are Applied – The Mediums Used to Activate Brake Systems

• Basic Fluid Dynamics (Hydraulics)

• Basic Air Dynamics (Pneumatics)

• Spring Dynamics

• Hydraulic Brakes

• Air Brakes – Basic Operation

• Air Brake System Configuration Variables

• Air Over Hydraulic and Air Park Systems

MODULE 2 – The Supply System

• Compressed Air, DANGER

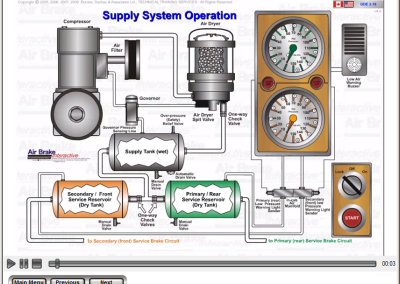

• Supply System – Introduction and Overview

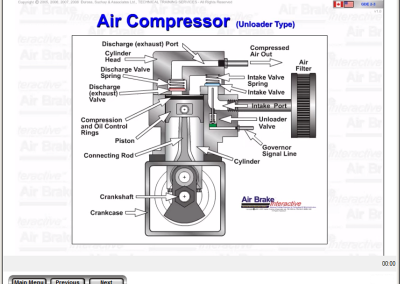

• Air Compressor Component Identification and Operation

• Air Compressor – Drives and Mountings

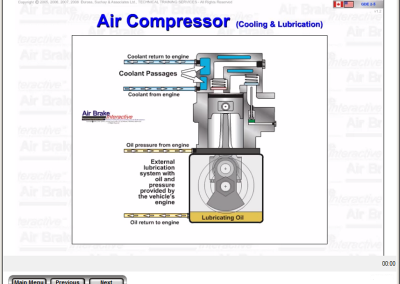

• Air Compressor Cooling and Lubrication

• Optional Compressor Induction System (Utilizing Turbo-Charger Boost Pressure)

• Air Dryer Types

• Desiccant Air Dryer – Component Identification and Operation

• Aftercooler Condensing Air Dryer

• Alcohol Evaporators & Injectors

• Governor

• Supply Tank & Service Reservoirs

• Safety Valve (Over-Pressure Relief Valve)

• One-way Check Valve

• Drain Valves (Manual and Automatic)

• Air Pressure Gauges

• Low Air Pressure Warning Devices

• Supply System Operation

• Pressure Ranges and Rise Times

MODULE 3 – The Service Brake System

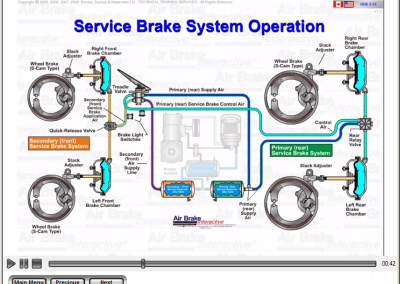

• Basic Service Brake System – Component Identification

• Brake Control and Synchronization (Quick Release and Relay Valves)

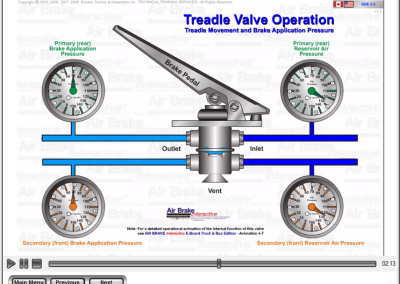

• Treadle Valve – Component identification and Operation

• Brake Pedal Feel (Feedback)

• Primary (Rear) Relay Valve

• Secondary (Front) Quick Release Valve

• Dry / Slippery Valve

• Secondary (Front) Service Brake Ratio / Limiter Valve (Limiting Valve)

• Brake Tubing and Hoses

• Service Brake Chambers – How they work, Component Identification and Operation

• Brake Chamber Stroke vs. Application Force

• Brake Chamber Size, Markings, Outside Diameter (OD) and Adjustment Limits

• Service Brake System Operation

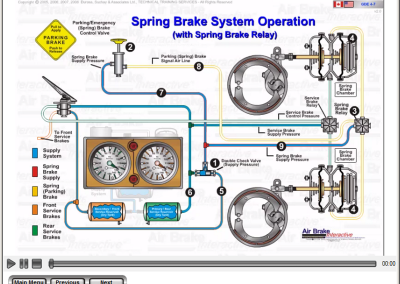

MODULE 4 – The Spring Brake System (Park / Emergency Brakes)

• Compressed Spring, DANGER

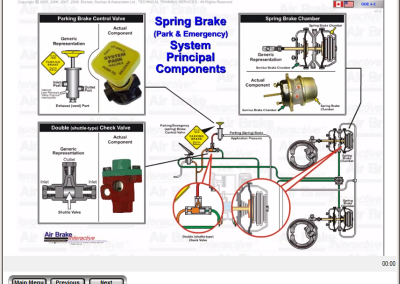

• Spring Brake System – Introduction and Principal Components

• Double Check Valve Design and Operation (Shuttle-type)

• Park / Emergency Brake Control Valve Operation

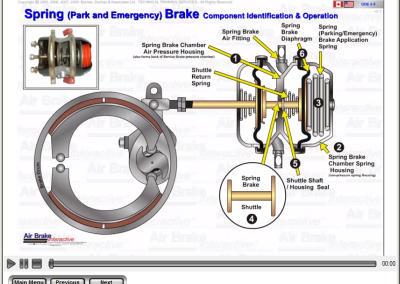

• Spring Brake Chamber – Component Identification and Operation

• Spring Brake System (Basic) with Quick Release Valve

• Spring Brake System with Relay Valve

• Brake Compounding

• Basic Anti-Compounding Circuit (with Standard Spring Brake Relay)

• Anti-Compounding Circuit (with Anti-Compounding Spring Brake Relay)

• Service Brake Application Force vs. Spring Brake Application Force

• Manual Spring Brake Caging

• DD-3 Brake Chambers

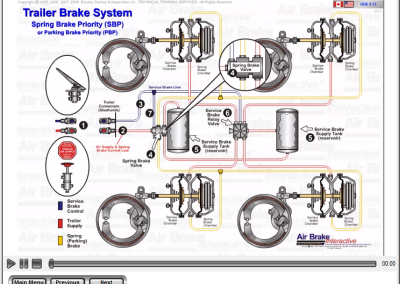

MODULE 5 – Trailer Brake Systems

• Introduction to Trailer Brake Systems

• Trailer Air Supply Circuit

• Trailer Air Supply Valve – Basic Function

• Combination Tractor Park and Trailer Air Supply Valves

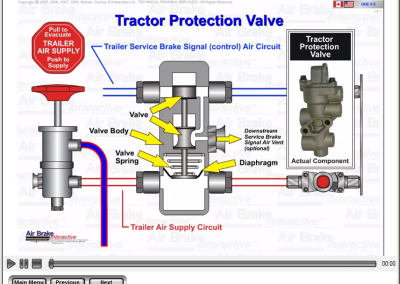

• Tractor Protection Valve

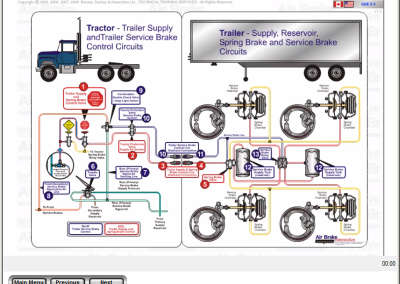

• Trailer Supply and Spring Brake System Operation (Tractor Section)

• Trailer Service Brake Control System Components

• Trailer Service Brake Control System Operation

• Trailer Brake Hand Valve (Spike) – Introduction, Warning

• Trailer Brake Hand Valve (Spike) – Component Identification and Operation

• Trailer Supply and Service Brake Connections (Gladhands)

• Trailer Brake System Configurations &Automatic Spring Brake Application Features

• Spring Brake Priority System Component Identification & Operation

• Service Brake Priority System Component Identification & Operation

• Trailer Relay Emergency (Pre-121) Systems – Introduction

• Trailer Relay Emergency (Pre-121) with Service Brake Chambers ONLY

• Trailer Relay Emergency (Pre-121) with Service & Spring Brake Chambers

• Trailer Relay Emergency (Pre-121 SERV) with Service & Spring Brake Chambers

MODULE 6 – Foundation Brakes (Wheel Brakes)

• Modern Foundation Brake Designs

• S-Cam Brake – Component Identification and Operation

• External (visible) S-Cam Brake Components

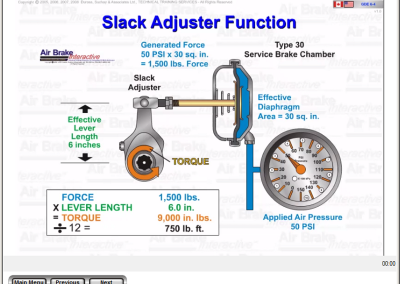

• Slack Adjuster – Basic Function, Leverage & Torque

• Slack Adjuster Types (Manual & Automatic)

• Wedge Brake – Component Identification and Operation

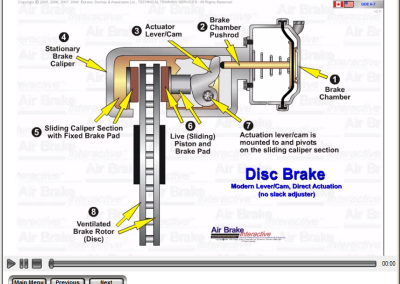

• Disc Brake – Component Identification and Operation

MODULE 7 – Demands on the Brake System During Vehicle Operation

• The Effects of Vehicle Speed and Weight on Stopping Distances

• Brake Lag and Stopping Distance

• Brake Fade (A Drum Brake Phenomenon)

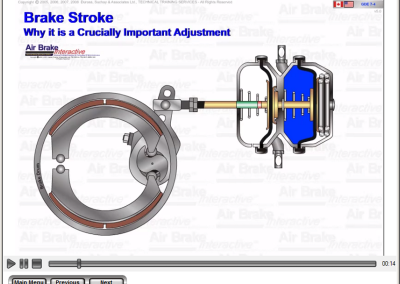

• Brake Chamber Stroke (A Crucially Important Adjustment)

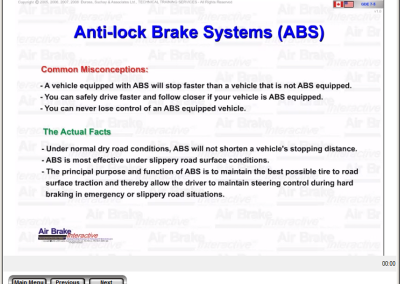

• ABS Fiction and Facts

• ABS Components and Operation

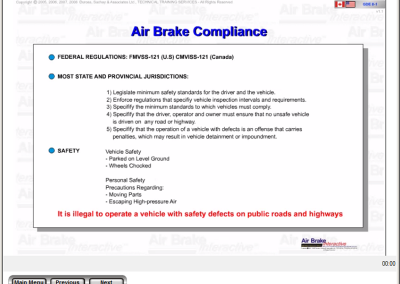

MODULE 8 – Air Brake Compliance

• Motor Vehicle Safety Standards

• Vehicle Security and Personal Safety During Vehicle Inspections

MODULE 9 – Inspecting Air Brake System Components

• Introduction to Brake System Inspections

• Vehicle Security / Compressor Inspection

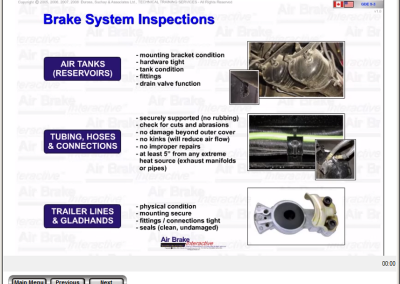

• Air Tanks, Lines and Fittings, Gladhands

• Brake Chambers, Slack Adjusters and Foundation Brakes

MODULE 10 – Air Brake System Functional Tests

• Air System Functional Tests: Introduction

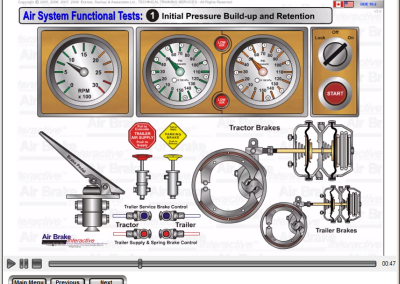

• Initial Pressure Build & Retention

• Tractor Park System (Spring Brake)

• Tractor Service Brake System and Tractor Protection Valve

• Low Air Warning System

• Pressure Rise-time Recovery (85-100 PSI) and Governor Cut-out

• Pressure Rise-time Recovery (50-90 PSI) and Governor Cut-out

• Compressor Cut-in

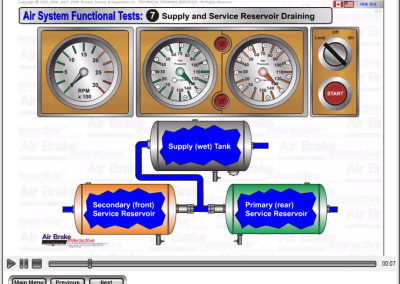

• Supply & Service Reservoir Draining

• Tractor Park & Service Brake (Dynamic Tests)

• Trailer Supply, Spring & Service Brakes

• Trailer Spring & Service Brake (Dynamic Tests)

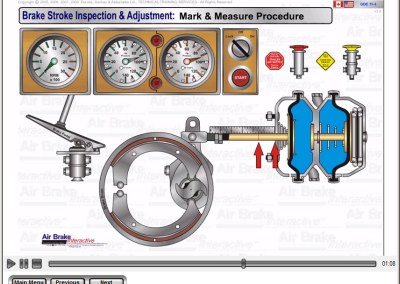

MODULE 11 – Inspecting Air Brake Adjustment

• Brake Stroke Adjustment – Introduction, (Component Wear & Brake Stroke)

• Brake Stroke Inspection & Adjustment (Before Checking Brake Chamber Stroke)

• Brake Stroke Inspection – Test Preparations & Equipment

• Brake Stroke – Mark & Measure

• Brake Stroke – Measure and Re-measure

• Brake Stroke Indicators

• Automatic Slack Adjusters (12-Pack-to-Go Initiating the Auto Adjust Process)

• Adjusting Manual Slack Adjusters

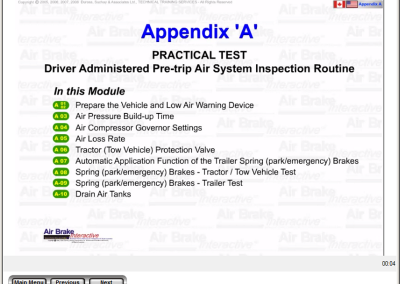

APPENDIX ‘A’ – PRACTICAL TEST – Driver Administered Pre-Trip Air System Inspection Routine

• Prepare the Vehicle and Low Air Warning Device

• Air Pressure Build-up Time

• Air Compressor Governor Settings

• Air Loss Rate

• Tractor (Tow Vehicle) Protection Valve

• Automatic Application Function of the Trailer Spring (park/emergency) Brakes

• Spring (park/emergency) Brakes – Tractor / Tow Vehicle Test

• Spring (park/emergency) Brakes – Trailer Test

• Drain Air Tanks

For more information and/or to discuss with one of our expert teaching resource developers, please contact:

Bryan Duross

TECHNICAL TRAINING SERVICES

Telephone: 519-621-0708

E-Mail: bduross@sentex.net